What Are The Five Whys? 5 Whys Root Cause Analysis Explained!

Have you ever encountered never-ending problems in your professional or personal lives? In their problem-solving and continuous improvement journey, organizations find challenges that require intensive research to reach their root causes. Sometimes, finding the leading cause of problems that make your processes inefficient is hard. The 5 Whys Root Cause Analysis is one of the most effective techniques for the same. Principles of systematic inquiry guide this method and allow teams to delve into problems at a root level to unravel the underlying causes. This method makes way for sustainable solutions.

Through this blog, let’s delve into the concept of root cause analysis, how it works, and its practical applications in various industries. It also shows 5 why examples and templates.

What Are The 5 Whys?

Let’s discuss what are the 5 whys. It is a structured problem-solving approach developed by Toyota as part of its continuous improvement practices within the Toyota Production System.

Sakichi Toyoda, the father of the Japanese industrial revolution and the founder of Toyota Industries, introduced the concept of asking a simple question – ‘Why’ to business problem-solving. He developed a managerial problem-solving tool called 5 Why Root Cause Analysis.

It is a straightforward yet powerful tool; it simply asks “why” with regard to any problem until its root cause is found. It gets its name from the idea that it generally takes around five times of saying “why” to unravel an issue to its root cause. However, the number isn’t fixed but is rather contingent on the complexity of the problem.

This number of asking “why” can increase or decrease depending on the complexity of the problem. Simpler problems might need fewer times of asking “Why”. Similarly, Larger problems may require more questions to discover the actual cause of the problem.

Owing to its effective and lean nature, this Root Cause Failure Analysis (RCFA) Tool has gained popularity. You must have understood what are the 5 whys of root cause analysis. So, let’s discuss its benefits.

What Are The Benefits Of The 5 Whys Analysis?

Five Whys root cause analysis method offers multiple benefits to organizations and professionals who want to understand the actual reason behind a problem. Some of the key benefits are discussed as follows:

1. Identifying Root Causes

The 5 Whys method helps teams dig deeper beyond surface-level symptoms By systematically asking “why” multiple times. It ultimately helps to uncover the fundamental root causes of problems.

2. Improved Decision-Making

It gives insight that will be of use in decision-making and strategic planning. It establishes causes and ensures an understanding of what causes problems. It enables an organization to design, apply effective interventions, and utilize resources toward priority areas.

3. Simple and Time Saving

It is simple and requires very little training; hence, it is accessible to teams at any organizational level. Its simplicity encourages even novices to use it, thus making teams empowered to act in problem solving. It ensures that the team accurately recognizes the problem to be able to solve it in effective and efficient ways, hence allowing them to get back on track within the shortest time possible while maintaining the normal flow and levels of productivity.

4. Cost-Effective Solutions

Compared with treating symptoms, addressing root causes directly can lead to more efficient and cost-effective solutions. It means that the organization may focus resources on solving a problem to avoid recurring or repeating its cost.

5. Future Problem Prevention

It would also help organizations prevent a repetition of the problem in a similar manner because it helps to identify and mitigate the root causes. It provides a proactive approach that helps the organization build resilience and avoid future failures or disruptions.

6. Fosters Problem Solving team culture

5 Whys promotes a culture of questioning, learning, and innovation. The teams become habitual to questioning the core facts and challenging the status quo. Hence, continuing with the pursuit of deeper understanding will bring about continuous improvement and growth of the organization. This step of involving the employees in root cause analysis process helps employees take ownership and responsibility. This fosters a culture of accountability, collaboration, and improvement amongst the team.

When To Use Root Cause Analysis?

5 Why analysis is a tool commonly employed to determine the role and accountability of human and system processes in the event of a human error. It is used to understand the cause and effect of a problem to prevent similar occurrences in the future. You can use this technique for the below-mentioned tasks:

- Repetitive Issues: You can use it when you notice frequent problems or issues in a process or system.

- Complex Problems: It can be used in complex processes or operations where multiple factors are involved.

- Quality Control: 5 Whys is a tool to help a manufacturing or service industry find out defects, errors, or failures in the product or service, all in such a way that they never recur.

- Safety Incidents: All these analyses help businesses improve their safety management and come to know about the loopholes in the safety procedure for future hazards.

- Process Improvement: This technique is very much used by organizations at the time of process analysis to find out the inefficiencies or bottlenecks that are hindering high productivity or quality.

- Project Failure: Reason or reasons that have caused the project to fail to meet objectives or deadlines. Recommend corrective action for this and future projects.

How Do You Conduct 5 Whys Root Cause Analysis?

Here’s the 5 step process that can be used to determine the root cause of recurring business issues in the organization.

Form And Assemble The Team

Team selection is the first essential and critical step of the process. The Five Whys method suggests involving everyone who is affected by the problem in some manner. Team members should be chosen across shifts, departments, or regions. If you are dealing with a shop floor problem, include factory workers alongside your managerial team. It is crucial to make this a team exercise and be open to all perspectives. It is advisable to include a facilitator to steer these meetings.

Brief The Team

The next step is to give the meeting agenda and brief your team on the purpose of this 5 whys exercise. The original methodology recommends using a white paper/ whiteboard during this process instead of a computer. Ideally, the facilitator should write down the problem on the whiteboards to ensure the team is collectively aware of it. Allowing cross-discussion will help to formulate a more comprehensive problem statement. Often, defining the problem statement itself is half the solution.

Ask Whys

The facilitator should lead the conversation by asking the first why. They should encourage answers based on facts rather than assumptions or emotions. The focus should be on finding the root cause rather than the symptoms or complaints. The process can become a rather lengthy one if the answers are not precise. Sometimes there could be more than one root cause. The root causes should be one word or short phrases rather than lengthy statements.

Repeat Four Times

Each reason listed out in the previous step needs to be reframed into a question. The facilitator should be able to demonstrate the cause-and-effect relationship to the team. For example, if the cause listed in Step 3 was – ‘Reminder email wasn’t sent to the client’ it would have to be reframed into a question – Why wasn’t the reminder email sent to the client?

Repeat this step four times or until you have determined the root cause. 5 Whys technique is an exemplary method of dealing with problems arising from human error. This team problem-solving approach minimizes the risk of hurting sentiments. The team approaches the problem without playing the blame-game and searches for the solution together in a constructive manner.

This 5 Why method seeks to set in place processes and best practices to avoid the problem rather than assigning blame to a single team member. In other words, the cause needs to be as specific as possible. The team should avoid listing causes as human errors or employee inefficiencies.

Verify the Causes

Check the answers for common themes or patterns of root causes that could, if corrected, prevent recurrence of the problem. Verify that the root causes are indeed factors of the problem. Sometimes, further investigation or data analysis may be necessary to confirm the validity of the identified causes.

Define Solutions

Now, you have discussed all the sources of errors with your team. The next part is to define solutions. Brainstorm with your team and form possible solutions or action plans to rectify the problems. After this, you need to implement the solutions and track their effectiveness.

Follow Up & continuous improvement

Access the effectiveness of the implemented solutions consistently. Watch the problem so that it does not occur. Take care of the new problems arising. Use the insights developed from the analysis of 5 Whys to help the organization continually improve its processes, systems, and procedures. Build a learning and problem-solving culture.

5 Whys Examples

Now, you have understood the concept and learned about how to conduct the method. Let’s discuss some 5 whys examples to help you better equip yourself with the concept.

practical, real-life business scenario using five whys method

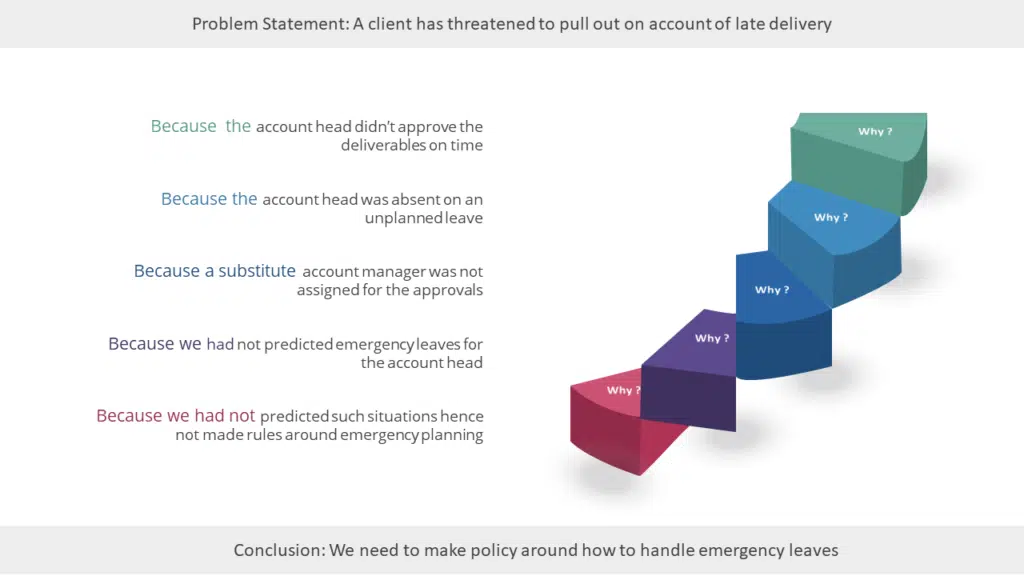

Example 1: A renowned advertising agency is facing an acute problem. A client has threatened to pull out due to the increasing delay in deliverables. The agency calls for a meeting of the responsible managers and executives.

- Why has the client raised the issue of late deliveries?

- There was one instance of late delivery.

- Why was there a delay in this instance?

- The creatives weren’t approved by the Creative Head as scheduled.

- Why were the creatives not approved within the stipulated period?

- The Creative Head was on sick leave for two days

- Why were the Creative Head’s responsibilities not delegated to a substitute?

- A substitute for the Creative Head hasn’t been appointed in the organization

- Why hasn’t a substitute been appointed?

- We hadn’t predicted the situation, and clients are becoming more particular about their deadlines.

Solution: To avoid delays, let’s designate a substitute for the Creative Head and some other critical profiles.

Let’s discuss another 5 whys example

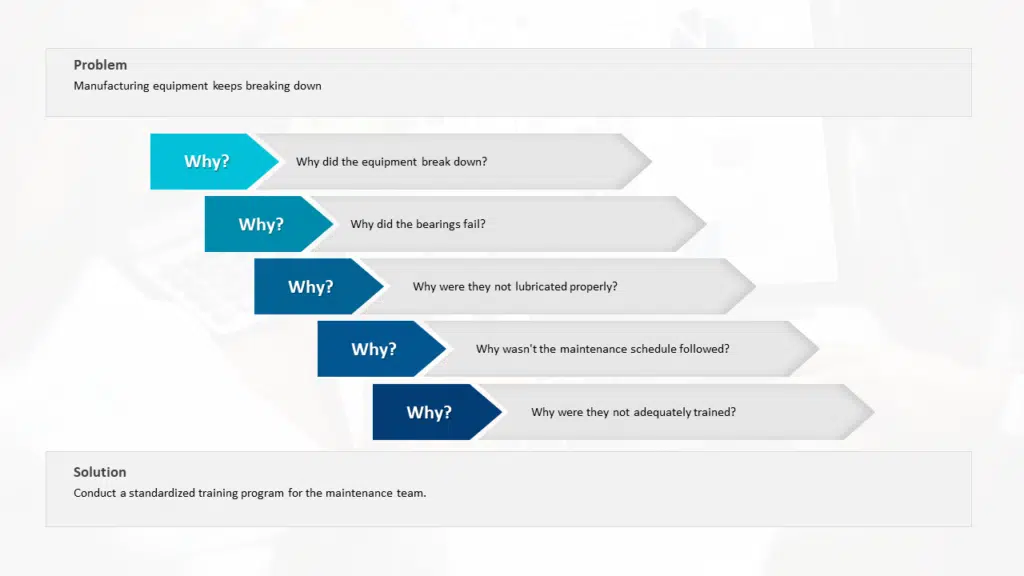

Example 2: Manufacturing equipment keeps breaking down.

- Why did the equipment break down? (First Why)

- Because the bearings failed.

- Why did the bearings fail? (Second Why)

- Because they were not lubricated properly.

- Why were they not lubricated properly? (Third Why)

- Because the maintenance schedule wasn’t followed.

- Why wasn’t the maintenance schedule followed? (Fourth Why)

- Because the maintenance team was not adequately trained.

- Why were they not adequately trained? (Fifth Why)

- Because there wasn’t a standardized training program in place.

Root Cause: Lack of a standardized training program for the maintenance team.

Solution: Conduct a standardized training program for the maintenance team.

These examples must have helped you how to conduct a 5 Y’s analysis. Lets discuss an example for professionals in their daily life

5 whys example for daily lives of professionals

Example 1: I am Feeling stressed and overwhelmed most of the time.

- Why am I feeling stressed and overwhelmed?

- Because I have too many tasks to complete.

- Why do I have too many tasks to complete?

- Because I need help with time management and prioritization.

- Why do I struggle with time management and prioritization?

- Because I don’t set clear goals or deadlines for my tasks.

- Why haven’t I set clear goals or deadlines?

- I often procrastinate and avoid planning.

- Why do I procrastinate?

- Because I feel overwhelmed and don’t know where to start.

Root Cause: Lack of clear goal-setting, deadlines, and effective time management strategies.

Solution: Set clear goals with deadlines.

5 Whys Root Cause Analysis Templates

After spending considerable time in Root Cause Analysis, you ought to present your Analysis in the most persuasive manner to influence decision-makers. Keeping that in mind, we have designed a collection of Templates for you. The templates’ design ensures the analysis is conveyed clearly.

Root Cause Analysis PowerPoint Template

You can use this List Template to showcase a structured approach to the root causes of the problem. The question ‘Why’ is asked repeatedly until the most basic answer, i.e., the root cause, comes up.

This Template has a list design that makes it easy for the audience to understand the sequence of problems listed. You can edit the slides with your preferred text. Add Background Images and colors to personalize this Template according to your brand identity.

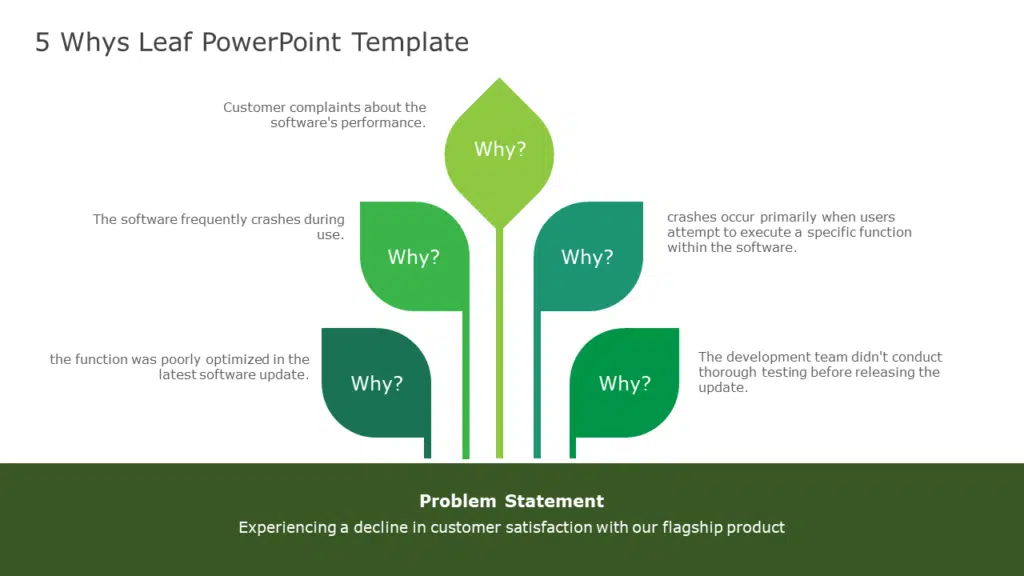

5 Whys Leaf PowerPoint Template

This framework uses attractive infographic vectors to break the problem into stages to find out the root cause affecting the business.

Using this approach, we can find the root cause of a problem and develop corrective or preventive solutions. It consists of five leaf petals that can denote the “Whys.” This beautiful leaf style makes the template beautiful and signifies an eco-friendly approach. The middle leaf indicates the main why, and the following leaves denote the subsequent whys. Simply download this template and customize it to your preferences.

Animated 5 Whys Business Analysis PowerPoint Template

Use this template to illustrate the five causes of a business problem creatively. It performs a ‘5 Why Analysis’ using innovative animation. These animations make the presentation attractive and easy for your audience to comprehend.

Using this template, you can identify viable reasons for a business problem by asking 5 ‘Why’ questions. This framework helps you discover the root cause and, thus, formulate an effective solution accordingly. It has multiple slides to present each “Why” separately in a detailed manner. All the slides are fully editable, which you can personalize to suit your brand’s identity.

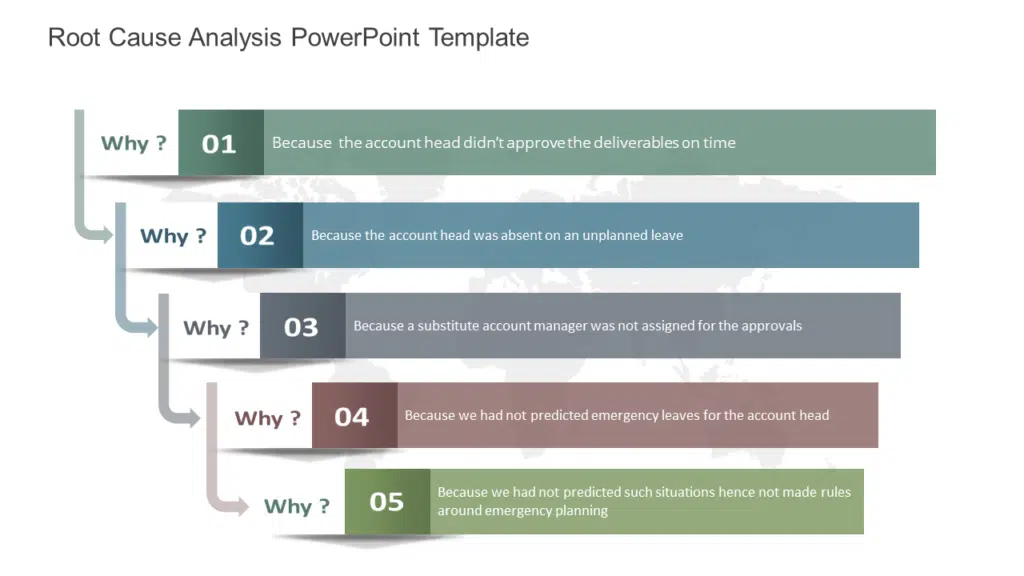

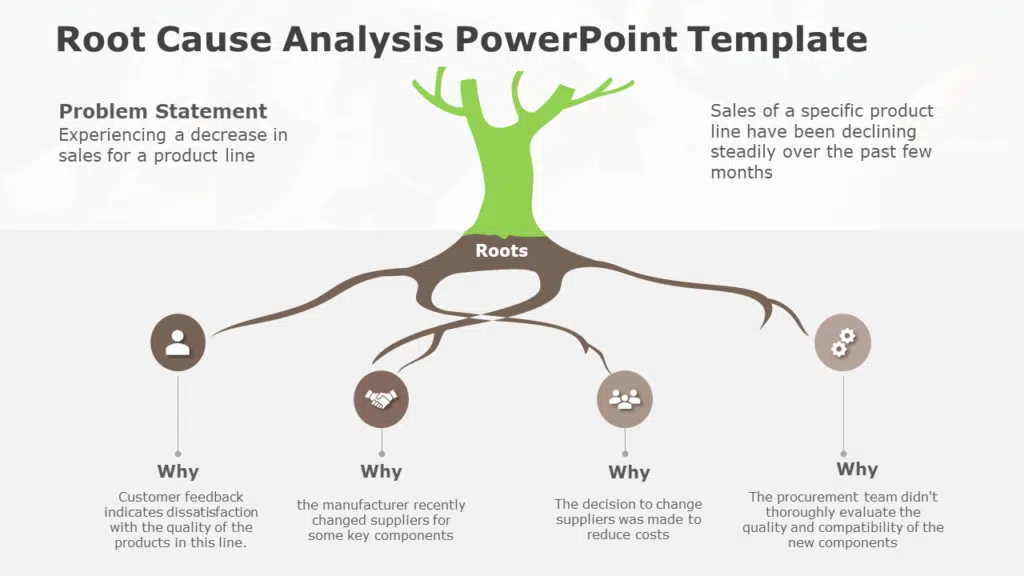

Root Cause Analysis PowerPoint Template

Our template on Root Cause Analysis with the Tree Design is a very good and visually appealing tool to easily identify and address the issues by any person, individual, and organization. The structure of the tree then outlines the possibility to document the problem statement, primary and secondary causes, and the recommended solutions.

It has personalizable fields and a user-friendly interface that enhances navigation and ease in collaborations among members of the team. In manufacturing, it allows the teams and, in fact, those of the healthcare and project management industries, among others, to be in a position whereby they can draw insights from a perspective of driving improvements effectively or preventing recurrence.

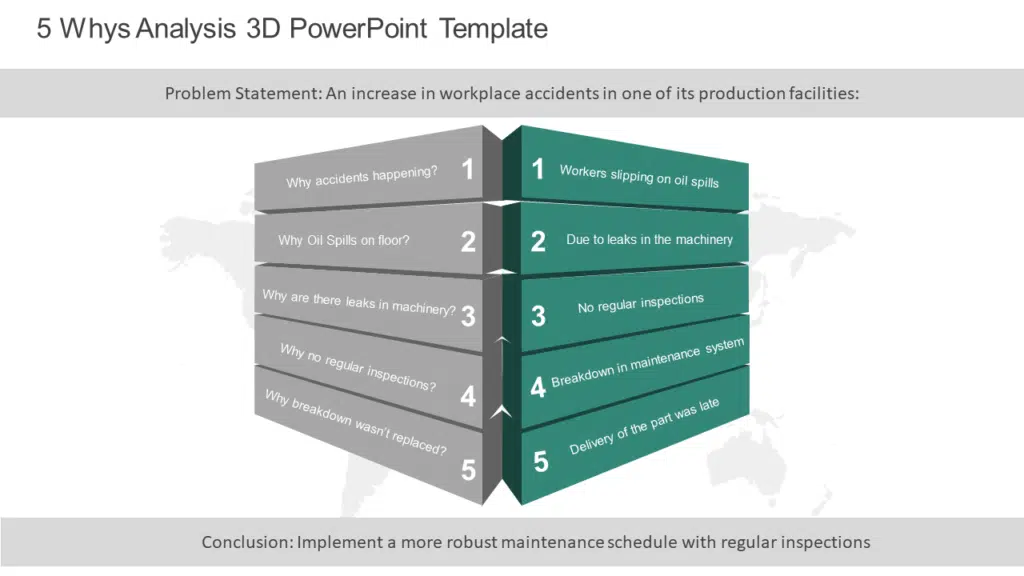

5 Whys 3D PowerPoint Template

This 5 y’s template incorporates 3D elements in its design. It has two sections represented with different colors. Both sections have five lists on which to write the problems and their answers. The left-sided section showcases the Whys, while the right-sided section answers the Whys.

It’s a beautiful presentation that helps the audience understand the problems and their solutions. It also provides a header and footer to write the Problem statement and Conclusion, respectively. The template is fully editable, and you can personalize it per your brand guidelines.

More Root Cause Analysis Templates

Browse through our Root Cause Analysis template collection for more suitable templates for your presentations. We also have a vast 5 Whys Template library that you can explore. All the templates are availabe for both MS PowerPoint and Google Slides format.

Conclusion

The ‘5 Whys ’ is an ideal problem-solving tool that both entrepreneurs and well-established companies can utilize. Using this approach, we can find the root cause of a problem and develop corrective or preventive solutions. Its success depends on the ability of the team to delve deep into root causes rather than stop at the symptom level. The investigating team should also be open to more than one root cause. This tool can have a substantial positive effect on your organizational process if performed correctly. Explore our PowerPoint Templates and enhance your presentations!

FAQs

-

How do I know when to stop asking "why" in a 5 whys?

Knowing when to stop asking “why” depends on reaching a point where the answers lead to actionable insights or when the root cause becomes evident. It’s important to use judgment and common sense to determine when further questioning won’t provide meaningful information.

-

Are there any limitations to this?

While it is a valuable tool for root cause analysis, it’s not always sufficient on its own. In complex situations, additional methods such as fishbone diagrams, fault tree analysis, or statistical analysis may be necessary to fully understand the problem.

-

Can the 5 Whys method be applied to personal life?

Yes, the five Whys method can be applied to personal life to address various challenges, such as time management, relationship issues, health concerns, and personal development goals.